Protective Clothing and Safety Gear for High-Pressure Water Work

Laor Engineering places great emphasis on safety when working with high-pressure water. One of the key tools for ensuring safe work is the use of

Laor Engineering places great emphasis on safety when working with high-pressure water. One of the key tools for ensuring safe work is the use of

Laor Engineering represents a range of leading international manufacturers in the field of high-end equipment and accessories for high-pressure water cleaning.

Laor Engineering is recognized as a leader in the field of cleaning and disinfecting water reservoirs, pools, and drinking water tanks.

Laor Engineering Ltd. possesses the equipment, knowledge, and experience for performing concrete crushing and cutting using the hydrodynamic (high-pressure water) method.

Wind turbines generate clean, green electricity; they replace polluting electricity production from burning fossil fuels in power plants, thereby reducing air and environmental pollution.

Laor Engineering carries out a wide range of industrial painting and protective coating projects, including all required surface preparation stages, under the company’s engineering supervision.

The work is performed using dedicated equipment and high-quality materials, with strict adherence to safety standards.

The process industry in Israel and worldwide suffers from both process-related corrosion and environmental corrosion.

Environmental corrosion depends on the proximity to the sea or to plants that emit polluting or acidic vapors.

Paint removal (including epoxy coatings) using high-pressure water is currently the leading method worldwide. With the appropriate equipment, old paint or epoxy coatings can be

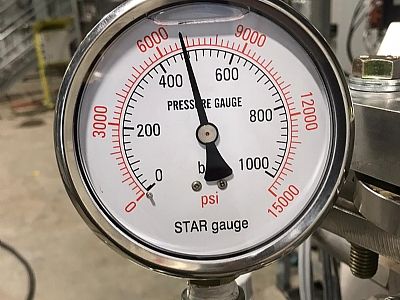

Pressure tests are recognized in industry as an engineering method for examining a product’s ability to withstand the pressure applied to it. Water pressure tests,

Passivation is a chemical process whose purpose is to improve durability by causing one material to become inert with respect to another (for this reason, the process is also referred to as “inertization”). Its uniqueness lies in the fact that it is carried out in air.

The use of tanks in industry requires regular maintenance and daily care.

Blasting cleaning is a technique in which a material or liquid (usually water) is sprayed at high speed toward a surface using dedicated equipment and compressed air.

In soda blasting, sodium bicarbonate (baking soda) is used as the blasting medium, allowing for effective cleaning while remaining gentle on the treated surface.

High-pressure water cleaning is performed using pumps capable of pressures up to 2800 bar and high flow rates. The simultaneous use of multiple pumps can further increase cleaning efficiency and coverage, allowing for the removal of stubborn deposits, dirt, and other contaminants from surfaces and equipment.

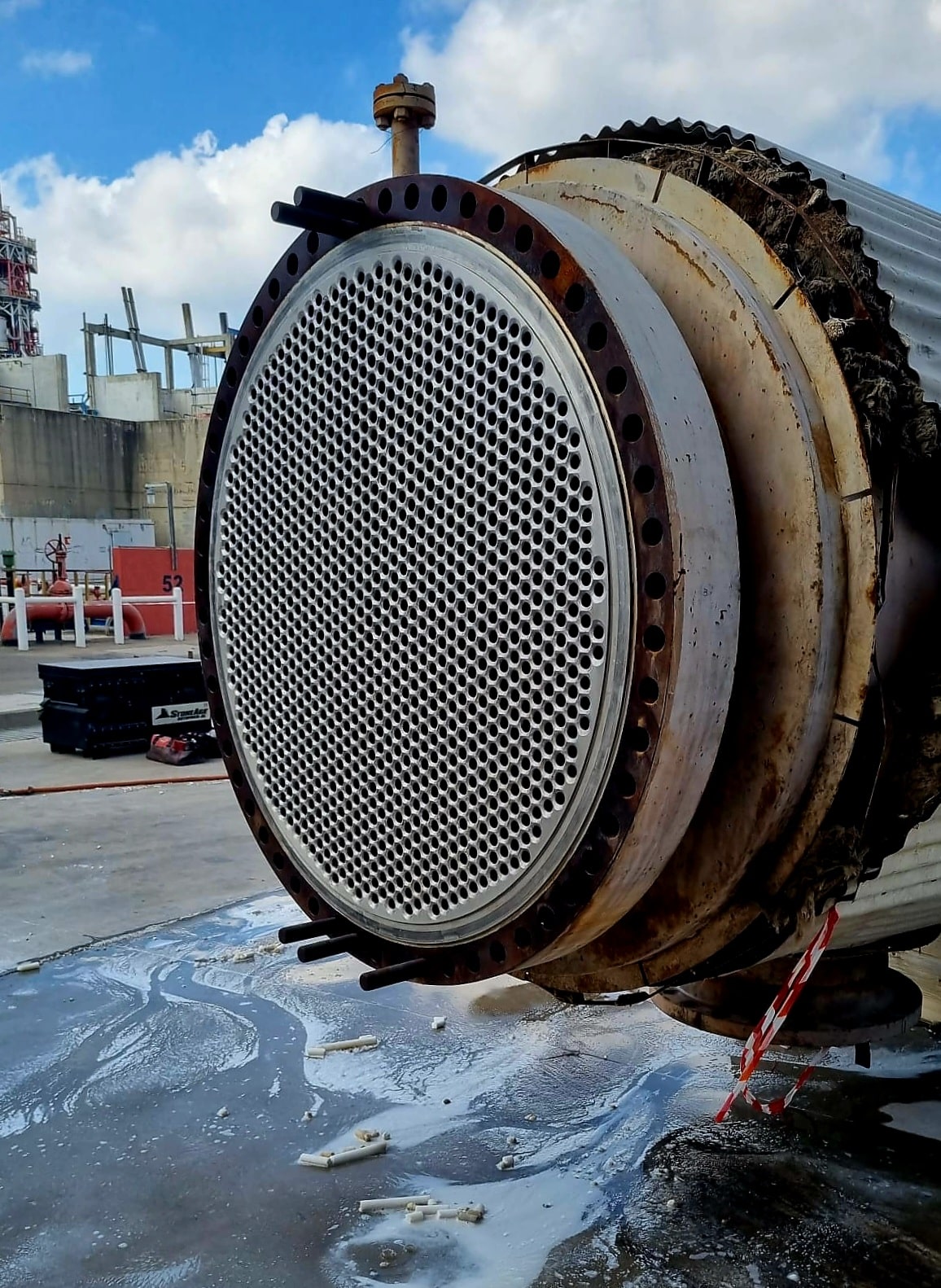

Heat exchangers are widely used across various industries, including refineries, desalination plants, power generation stations, HVAC systems in food factories, and numerous other industrial facilities. Heat exchangers play a critical role in transferring heat efficiently between fluids, ensuring optimal process performance and energy efficiency.

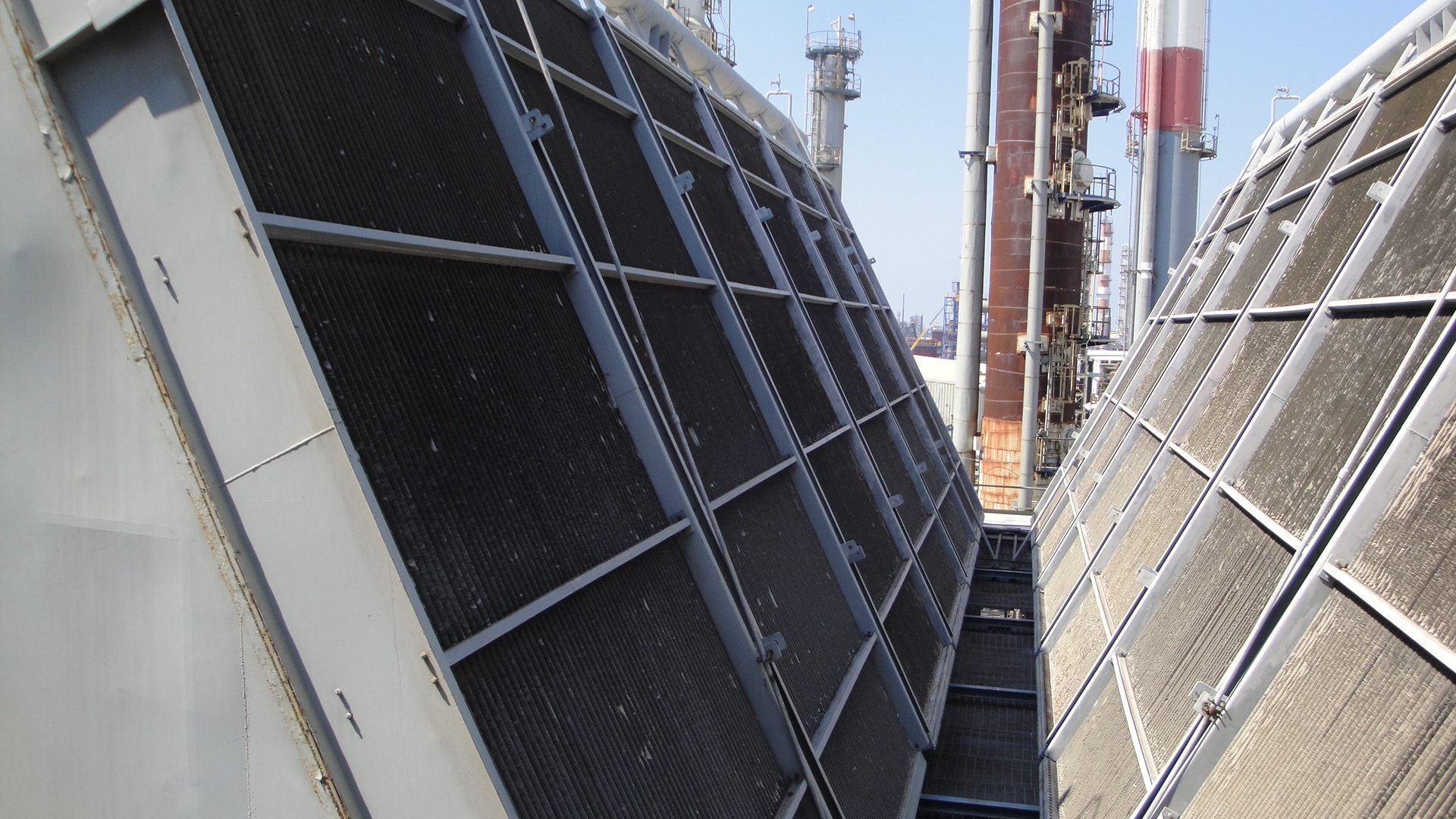

Regular cleaning and disinfection of HVAC systems are essential to ensure optimal air quality, energy efficiency, and the longevity of the equipment. Over time, dust, dirt, microbial growth, and other contaminants accumulate in ducts, coils, and filters, which can reduce system efficiency, increase energy consumption, and pose health risks to building occupants.

Client: A leading food company in Israel.

Case: Corrosion had formed on the inner shell of a stainless steel tank used for salt storage.

Treatment: A two-step cleaning procedure was carried out to passivate the stainless steel and restore its

Fire-resistant construction in industrial furnaces and steam boilers.

Furnaces and steam boilers play a vital role in a wide range of industrial processes, providing the necessary heat required for production and processing operations. These systems operate under extreme temperatures, making fire-resistant construction essential for safety, efficiency, and long-term reliability.

To understand the importance of condenser cleaning, it is first recommended to become familiar with condenser systems. These systems are designed for cooling – water