NLB High-Pressure Pumps

Laor Engineering is the proud distributor and representative of NLB, a global leader in the manufacturing of high-pressure pumps and related equipment. In addition to

Laor Engineering is the proud distributor and representative of NLB, a global leader in the manufacturing of high-pressure pumps and related equipment. In addition to

Chillers are essential cooling systems widely used throughout all sectors of the industry. While chiller operation is highly effective, water-cooled systems are inherently susceptible to

Cooling towers integrated into HVAC and refrigeration systems are constantly exposed to various contaminants due to the vast quantities of water passing through them daily.

Maintenance challenges in industrial plants necessitate a combined cleaning process. Over time, the efficiency and effectiveness of heat exchangers, condensers, and cooling systems are compromised,

Ultra-high pressure water cleaning and washing is performed using pumps capable of pressures of up to 2,800 bar.

The pump, with a flow rate of 38 liters per minute, enables penetration, removal, and effective cleaning of even the toughest deposits and contaminants.

In cooling and air conditioning systems, the condenser is the Achilles’ heel of the facility in terms of maintenance requirements.

The condenser requires regular attention, and neglecting it can lead to a reduction in the system’s cooling capacity, up to complete shutdown. Additionally, a significant portion of the system’s energy losses occurs at the condenser.

Blasting cleaning is a technique in which a material or liquid (usually water) is sprayed at high speed toward a surface using dedicated equipment and compressed air.

In soda blasting, sodium bicarbonate (baking soda) is used as the blasting medium, allowing for effective cleaning while remaining gentle on the treated surface.

High-pressure water cleaning is performed using pumps capable of pressures up to 2800 bar and high flow rates. The simultaneous use of multiple pumps can further increase cleaning efficiency and coverage, allowing for the removal of stubborn deposits, dirt, and other contaminants from surfaces and equipment.

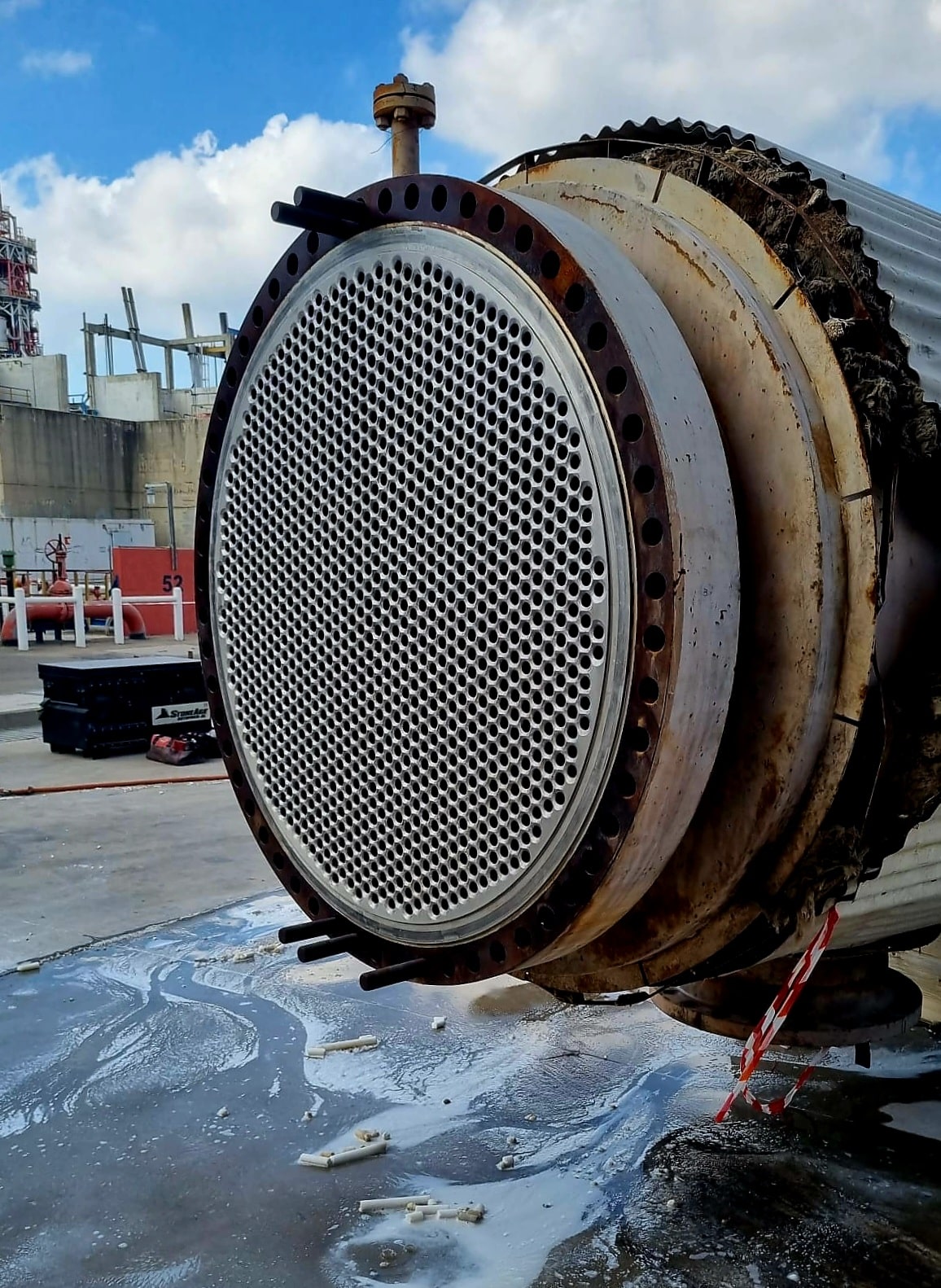

Heat exchangers are widely used across various industries, including refineries, desalination plants, power generation stations, HVAC systems in food factories, and numerous other industrial facilities. Heat exchangers play a critical role in transferring heat efficiently between fluids, ensuring optimal process performance and energy efficiency.

To understand the importance of condenser cleaning, it is first recommended to become familiar with condenser systems. These systems are designed for cooling – water

What Is Chemical Cleaning and Where Do You Start? Laor Engineering Ltd. performs chemical cleaning of heat transfer surfaces, pre-commissioning chemical cleaning, and general surface

Innovative, efficient, and effective cleaning method A wide range of industries around the world use dry ice blasting as a method for surface cleaning, surface

Lahor Engineering Ltd. operates a machine for cleaning and washing heat exchanger tube bundles. Heat Exchanger Tube Bundle Cleaning Machine in Operation at Haifa Refineries

Laor Engineering provides specialized mechanical cleaning services for industrial Shell & Tube heat exchangers. This process utilizes high-performance scrapers (projectiles) that are propelled by water